2025 didn’t bring dramatic upheaval for electronics manufacturing, but it did bring clarity. Instead of headline-grabbing shifts, the year was shaped by steady, practical changes that influenced how businesses ran day-to-day. Supply chains settled, expectations tightened, and manufacturers doubled down on the things that genuinely make a difference: stable chemistry, good data, and reliable support.

Reflecting on the year through that lens gives a clearer picture of what’s ahead for 2026.

Supply chains steadied, and expectations got sharper

After several turbulent years, 2025 felt more predictable. Materials moved more freely, logistics improved, and lead times were far less of a guessing game. That stability, however, revealed a pattern manufacturers spoke to us about repeatedly: consistency matters just as much as availability.

Even when products arrived on time, the focus was on how they behaved on the line. Subtle formulation changes, natural ageing of stock, or batch-to-batch variation had more visible consequences as processes became increasingly sensitive. Tighter specifications meant that chemistry simply needed to work the same way, every time.

Materials behaviour came under the microscope

Across PCB and electronics production, manufacturers told a similar story throughout the year. As features became finer and margins for error smaller, any drift in chemistry showed up quickly.

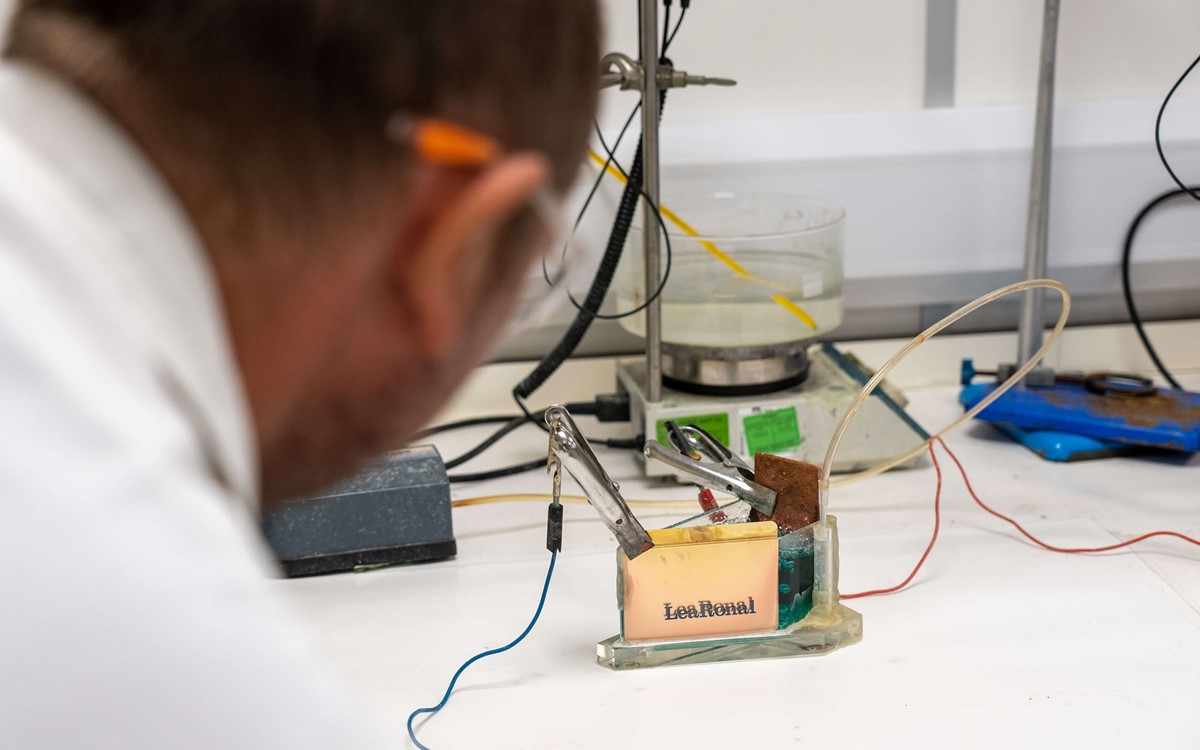

Developers based on carbonates, plating baths, etches and resist systems all reinforced the same principle seen across our technical discussions and analysis work. Predictable chemistry delivers predictable outcomes, and the tighter the tolerance, the more valuable stable behaviour becomes.

Regulation remained front and centre

PFAS and UK REACH discussions continued throughout the year, and many manufacturers used 2025 to get ahead of future change rather than wait for it.

We saw more requests for documentation, clearer evidence of material behaviour and transparent supply chain information. Our article on PFAS illustrated this shift well. Manufacturers wanted practical clarity rather than speculation, especially where niche chemistries play a critical role in processes that don’t have straightforward alternatives.

While final regulatory decisions are still evolving, the direction of travel is consistent. Processes that rely on specialist chemicals will need stronger traceability and more informed decision-making. Many customers approached us proactively to understand what future-ready compliance looks like.

Demand patterns moved, but quality expectations didn’t

Some consumer-led segments fluctuated, while industrials, automotive and other critical-systems sectors remained steady and often busy. Despite those differences, the message across the board was the same: quality expectations continued to rise.

Specifications became tighter, documentation requirements expanded, and audits became more frequent. Whether a customer was producing high-density PCBs or sensitive imaging components, confidence in material performance was central to achieving yield and keeping production efficient.

Accessible expertise mattered more than ever

One of the strongest themes of 2025 was the value of being able to get answers quickly.

Manufacturers increasingly sought support that was practical, clear and grounded in real process knowledge. This aligned closely with how we work every day, providing lab analysis, material interpretation and hands-on troubleshooting to help keep lines running consistently.

The contrast between automated global helplines and responsive, knowledgeable technical teams became even more apparent. Expertise wasn’t a nice-to-have; it was part of keeping production stable.

What didn’t change in 2025

Even with evolving pressures, several fundamentals stayed the same:

- Stable chemistry still underpins stable production

- Good process control continues to drive yield

- Quality expectations only move upward

- Manufacturers choose reliability over risk

- Strong supplier partnerships reduce uncertainty

What 2026 is shaping up to look like

While the industry should always be careful with predictions, the trends moving into next year are clear:

- Material consistency will carry even more weight than availability

- Regulatory awareness, particularly around PFAS, will remain part of day-to-day decision-making

- Analysis and monitoring will continue to drive process stability

- Manufacturers will expect clearer, faster support from suppliers

- Sustainability reporting will reach further into chemical supply chains

What 2025 reinforced is that stability doesn’t come from supply alone. It comes from understanding. It comes from clarity. And often, it comes from working with partners who make complex topics practical.

As manufacturers prepare for 2026, the businesses that thrive will be the ones that combine strong process control with dependable expertise. If you would like to stay informed on chemical developments or discuss materials considerations for the year ahead, our team is ready to help.