The technological landscape is now being redefined by flexible electronics, which offer transformative possibilities across a wide range of industries, including healthcare, consumer electronics, automotive and energy, and printable inks lie at the centre of this innovation. These are materials that have been designed to enable the fabrication of electronic devices that are lightweight, bendable, and yet still durable. As they have been able to seamlessly integrate into flexible substrates using advanced printing techniques, printable inks are now unlocking new avenues for product design and functionality.

Understanding printable electronic inks.

Printable electronic inks are specialised formulations that incorporate conductive, semiconductive or insulating materials and can be deposited on flexible substrates like paper, plastic or fabric. These can then form the functional components of electronic circuits.

The key materials used in printable inks, include metallic nanoparticles like silver, gold or copper to create conductive pathways and organic semiconductors, which are used in devices like organic light-emitting diodes (OLEDs) and organic photovoltaics. Printable inks also use carbon-based materials such as graphene or carbon nanotubes, as these are known for their superior conductivity and flexibility as well as dielectric polymers, which are essential for insulating layers.

Electronic inks are applied using both traditional and emerging printing techniques. Screen printing is ideal for large-area patterns whilst inkjet printing offers high precision for detailed circuit designs. They can also be used as part of gravure printing which is suited for high-speed roll-to-roll manufacturing and flexographic printing which is a cost-effective method for flexible enjoyable patterns.

Once these inks have been printed and cured, they then form the active and passive components of electronic circuits, which enables functionalities such as sensing, energy storage and signal processing.

Applications of flexible electronics

Flexible electronics are now a significant feature of wearable technology. Printable inks are essential for creating stretchable sensors, fitness trackers and smart fabrics. These devices can provide real-time health monitoring and integrate seamlessly into our daily lives, offering both comfort and durability.

They are also prevalent in the healthcare sector as flexible electronic patches equipped with printed sensors are now being developed to help with non-invasive diagnostics like monitoring heart rates, hydration levels and glucose levels, and as they are lightweight in nature, they can ensure patient comfort and ease of use.

Electronic printable inks are also being used in the production of thin-film solar cells, which enable lightweight and portable energy solutions. These cells are being integrated not only into building materials but also into clothing and even mobile devices.

There are now an increasing number of consumer electronic items that benefit from bendable displays, including foldable smartphones. These rely on flexible circuits that have been fabricated with printable inks, as their adaptability allows for more innovative designs that can appeal to the needs of the modern consumer.

In the automotive industry, printed flexible sensors and displays are being incorporated into vehicle interiors to enhance user interfaces and monitoring systems.

Future developments in printable inks

The field of flexible electronics is continuing to grow and develop at a rapid rate, and so ongoing advancements in printable inks are expected to help drive the industry forward. Researchers are now developing inks that enhance electrical conductivity and thermal stability to meet the demands of high-performance devices. There is also a move to become more sustainable so biodegradable and recyclable inks are being worked on with things like organic semiconductors and conductive polymers being explored as alternatives to the metal-based inks to reduce their environmental impact.

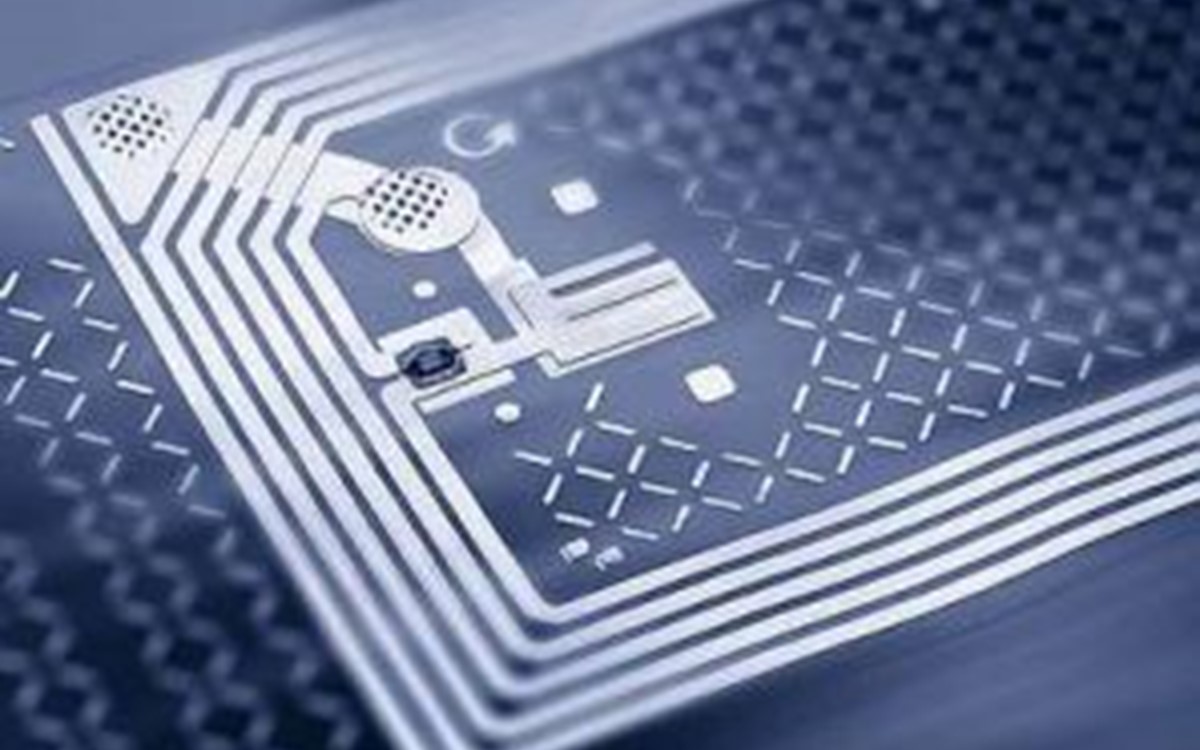

As part of the integration with the Internet of Things, printable inks are expected to enable the creation of smart labels, RFID tags and environmental sensors to monitor conditions and transmit data in real-time.

More efficient and precise fabrication processes are also being developed thanks to the combination of additive manufacturing and printable inks. 3D printing with conductive inks will allow for the creation of complex multi-layered electronic structures. There is also a move to enhance roll-to-roll printing techniques in order to increase the scale of production to make flexible electronics more accessible and cost-effective.

Flexible electronics are likely to become an even more significant feature in many different industries and these will be powered by printable inks. Whether it is personalised healthcare solutions, sustainable energy or smart consumer devices, there is no end to the possibilities that are available. Printable inks are likely to play a crucial role in shaping a more connected and adaptable world as material science and manufacturing technology evolve. This means that consumers and industries can both embrace the potential of flexible electronics, as there are greater opportunities for innovation, efficiency and improved quality of life.