Analysts predict the global semiconductor market will surpass a trillion dollars by 2030, and the demand is only accelerating. In the wake of COVID, supply chain shocks revealed just how dependent the world has become on tiny chips of silicon, not just for smartphones and AI servers, but for everything from cars and appliances to doorbells and toothbrushes. With production delays and soaring prices hitting multiple sectors, governments worldwide have pledged billions to ramp up semiconductor manufacturing and reduce reliance on fragile global supply chains.

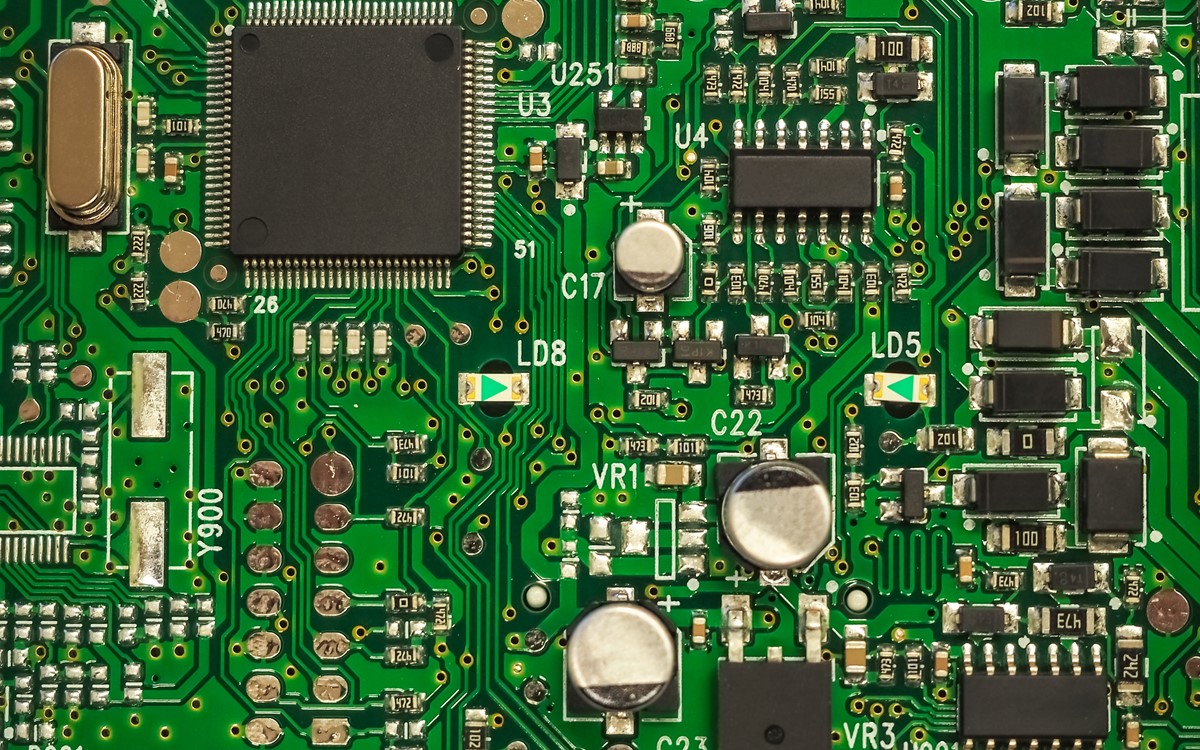

But while attention and investment are focused on chip fabs, there’s another essential piece of the puzzle quietly underpinning it all: the printed circuit board (PCB). These green, blue or even black and red layers are what hold chips in place and connect them to the rest of the system, delivering power, enabling memory, and making functionality possible. If chips are the brains, PCBs are the nervous system. And they too are under pressure. From material shortages to increasingly strict chemical regulations, PCB production is facing its own set of challenges just as demand reaches an all-time high.

The vital role of PCBs in electronics manufacturing

Every microchip needs a home, and PCBs provide the physical platform and connectivity that allow components like processors memory and sensors to work together. Without PCBs, even the most advanced chips will be useless. In addition to this, with electronics becoming more powerful and compact, PCBs are becoming increasingly complex. Modern devices require high-density multilayer boards that can handle faster data speeds, greater thermal loads and tighter tolerances. With industries like automotive, aerospace, telecommunications and healthcare all racing to develop smarter technologies, the performance and reliability of PCBs has never been more important.

However, in the rush to scale up chip manufacturing, PCB production has faced its own unique challenges, from material supply issues to increasingly complex regulations around chemical use and environmental compliance.

The challenges facing PCB manufacturers

-

Rising material and process demands

Advanced PCBs rely on a variety of specialist materials including copper, resins, glass fibre, photoresists, plating chemicals and surface finishes. If there is any disruption in the supply chain for these can delay production and impact the quality of the device. With these devices becoming smaller and more powerful, manufacturers also need to ensure that tighter process control during imaging, plating, etching and final cleaning is in place, all while managing costs and sustainability goals.

-

Chemical safety and compliance

PCB manufacturing involves a range of chemical processes that are now under increasing levels of scrutiny. Regulations like REACH and RoHS set strict limits on hazardous substances, while emerging rules around PFAS, are adding new pressure to switch to safer alternatives or implement tighter controls.

This means manufacturers not only need access to compliant products but also require support in understanding how the new legislation is likely to affect their operations, and how to maintain quality while staying ahead of compliance requirements.

-

Sustainability and supply chain resilience

Sustainability is no longer optional for most businesses. The electronics industry faces growing demands to reduce environmental impact, and so manufacturers are under pressure to use more eco-friendly materials, manage waste responsibly and reduce carbon emissions across their supply chains. At the same time, events like the COVID-19 pandemic, global shipping issues and geopolitical tensions have shown exactly how fragile the international supply chain can be, securing a reliable supply of high-purity chemicals and critical equipment, preferably from local trusted partners, is now a strategic priority.

What is being done?

While chip fabs might grab the headlines, innovation is also happening quietly behind the scenes in order to support PCB manufacturers. Suppliers are working more closely with customers to co-develop new chemistries, reduce hazardous substances and optimise performance in line with the industry demands.

Technical services and lab analysis are helping manufacturers to achieve consistent results, reduce rework and adapt to new design requirements. With sustainability at the forefront of everyone's mind, there’s a renewed focus on improving resource efficiency, from better process control to reducing chemical consumption and managing waste more responsibly.

How A-Gas Electronic Materials supports the PCB and semiconductor sector

This is where A-Gas Electronic Materials plays a key role - by supplying the high purity chemicals, equipment and technical support that’s needed to keep production lines running smoothly. A-Gas offers a wide portfolio of specialist chemicals used in PCB and electronic manufacturing. These products are sourced through trusted supply chains and meet the stringent standards required by high precision manufacturing operations. They also provide equipment that supports plating and finishing operations, helping customers to maintain reliable, consistent performance across every batch.

What sets A-Gas apart is their dedicated laboratory and field-based technical team. Customers can access testing services to ensure chemical stability and process accuracy. This analytical support helps manufacturers to improve process control, reduce downtime and make data-led decisions.

Based in the UK, A-Gas Electronic Materials offers local warehousing and technical support to help manufacturers reduce supply chain risk, stay compliant and respond quickly to changes in demand.

As the global race to produce more chips continues, it’s vital not to lose sight of the full electronics ecosystem. PCBs are not glamorous, but they are indispensable. And if supply chains, chemical sourcing or process reliability falters, it creates a ripple effect that can halt innovation across entire industries. From compliance challenges to supply chain resilience, PCB manufacturers need reliable partners who understand the technical demands of electronics production and can deliver high quality products and support every stage. A-Gas Electronic Materials bring the chemical expertise, local availability and hands on support that help keep this critical part of the electronics supply chain running smoothly.

Get in touch to discuss your PCB requirements and discover how we can support your operations.