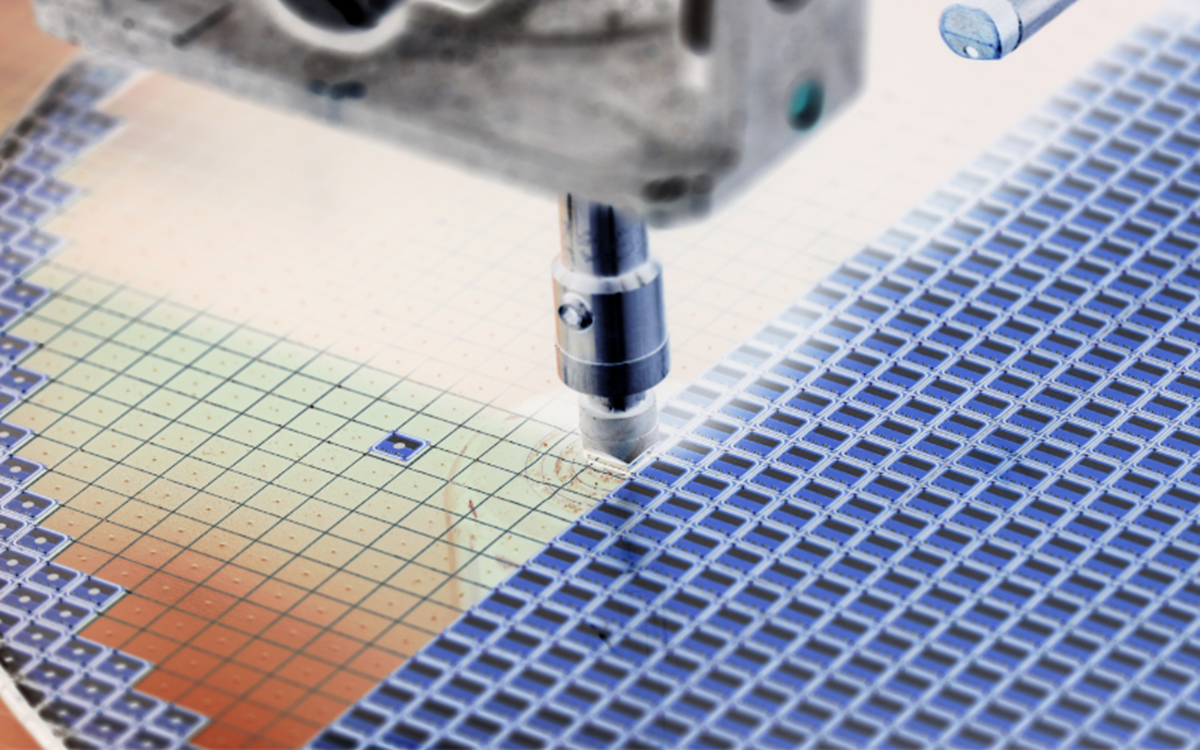

Semiconductors

We offer complementary, reliable, high-quality materials sets to support both today’s high-volume manufacturing processes and advanced technology for the future.

Semiconductors and A-Gas Electronic Materials

We develop solutions to address technology challenges that are critical to advancing diverse market drivers. We work closely with our customers to develop materials that meet their specific needs, including technical performance and cost-of-ownership improvements.

Our materials are valuable building blocks for todays advanced microelectronics, found in everything from consumer electronics to high-end data centers, automotive applications, medical devices, artificial intelligence, power electronics and more.